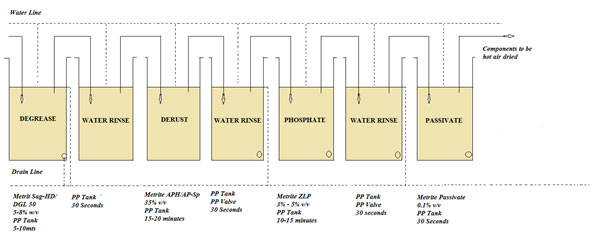

Iron Phosphate Pretreatment Systems. Iron phosphate systems, are used for parts that require a durable finish but are not exposed to severely corrosive environments. These systems can involve two to six stages, with the shortest sequence being a cleaner-coater stage followed by a tap-water rinse. Short sequence systems are employed if performance requirements are low.

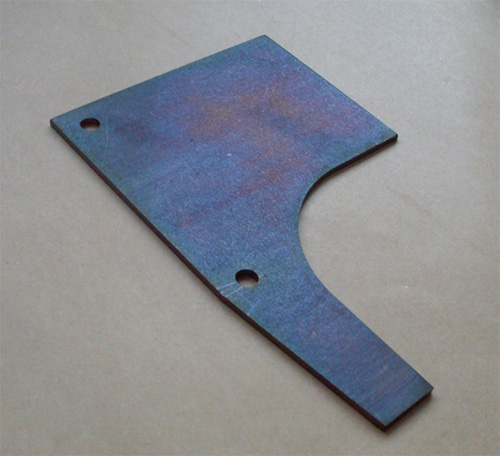

Iron phosphates produce an amorphous conversion coating on steel that ranges in color from iridescent blue to gray, depending on operating conditions and product formulation. Mixed metals may be treated with modified formulas that typically contain fluoride.

Iron phosphate processes are much easier to operate and require fewer process stages than zinc phosphating. However, iron phosphates do not provide the degree of corrosion protection imparted by zinc phosphates.

- Rinsing

Proper rinsing is a critical, yet often-overlooked step in the pretreatment process. The water rinse process stops chemical reactions from taking place and removes unreacted chemicals from a part’s surface. Effective water rinsing also minimizes the migration of chemicals from one processing stage to the next. For effective rinsing, keeping the rinse water fresh reduces the amount of contamination present on the surface of the parts.